ORDINARY CAR C52 SERIES

Many different kinds of vertical lathe, according to its structure and USES different, mainly divided into horizontal lathe, vertical lathe, lathes, turret lathe landing, uniaxial and multiaxial automatic lathe, semi-automatic lathe, copying and multiple blade lathe, back wheel lathe, CNC lathes and turning centers, etc.In addition, there are all kinds of specialized lathe, such as crankshaft lathe lathe, camshaft and relieving lathe and so on.Yu in a large number of mass production with the interpretation of the designed Yu lathe, notably the enzyme type lathe Yu is most common.

In the car, in order to get the required movement, needs through a series of driving the execution parts and power sources, or connect the implementation and execution parts, this connection is called transmission link.Form a series of transmission parts, transmission link is called the transmission chain.Transmission chain usually contains two types of institutions: one kind is fixed transmission mechanism transmission ratio and transmission direction, such as constant ratio gears, worm, worm gear pair, screw and nut pair, known as the constant ratio transmission mechanism;Another kind is in accordance with the requirements of processing can change the direction of the transmission ratio and transmission drive mechanism, such as the exchange of gear mechanism, sliding gear mechanism, the clutch gear mechanisms, etc., are collectively referred to as swap.Transmission chain (kinematic chain) can also be divided into internal and external contact two kinds.

(1) contact outside the chain transmission chain is contact between power supply and vertical lathe to perform a transmission chain.It allows to perform a get due to the speed of movement, and deliver a certain amount of power.The change of outside contact transmission chain transmission ratio, only affect productivity or wheat surface roughness, does not affect the formation of surface shape.

(2) in order to contact transmission chain of two or more than two unit movement of compound forming, the transmission link between execution and execution parts called in contact.The form of a series of links within the transmission parts called contact transmission chain.Contact transmission chain link within the relative speed between the execution of a () and relative displacement should have strict requirements, otherwise there is no guarantee that the need when cutting the correct trajectory.Contact, therefore, in the transmission chain transmission vice transmission ratio must be accurate, there should be no friction drive and transmission of instantaneous transmission ratio change.In the car with the threading tool cutting thread, the contact between spindle and tool post thread transmission chain, is a ratio has strict requirements in contact transmission chain, it can ensure thread need to distance.

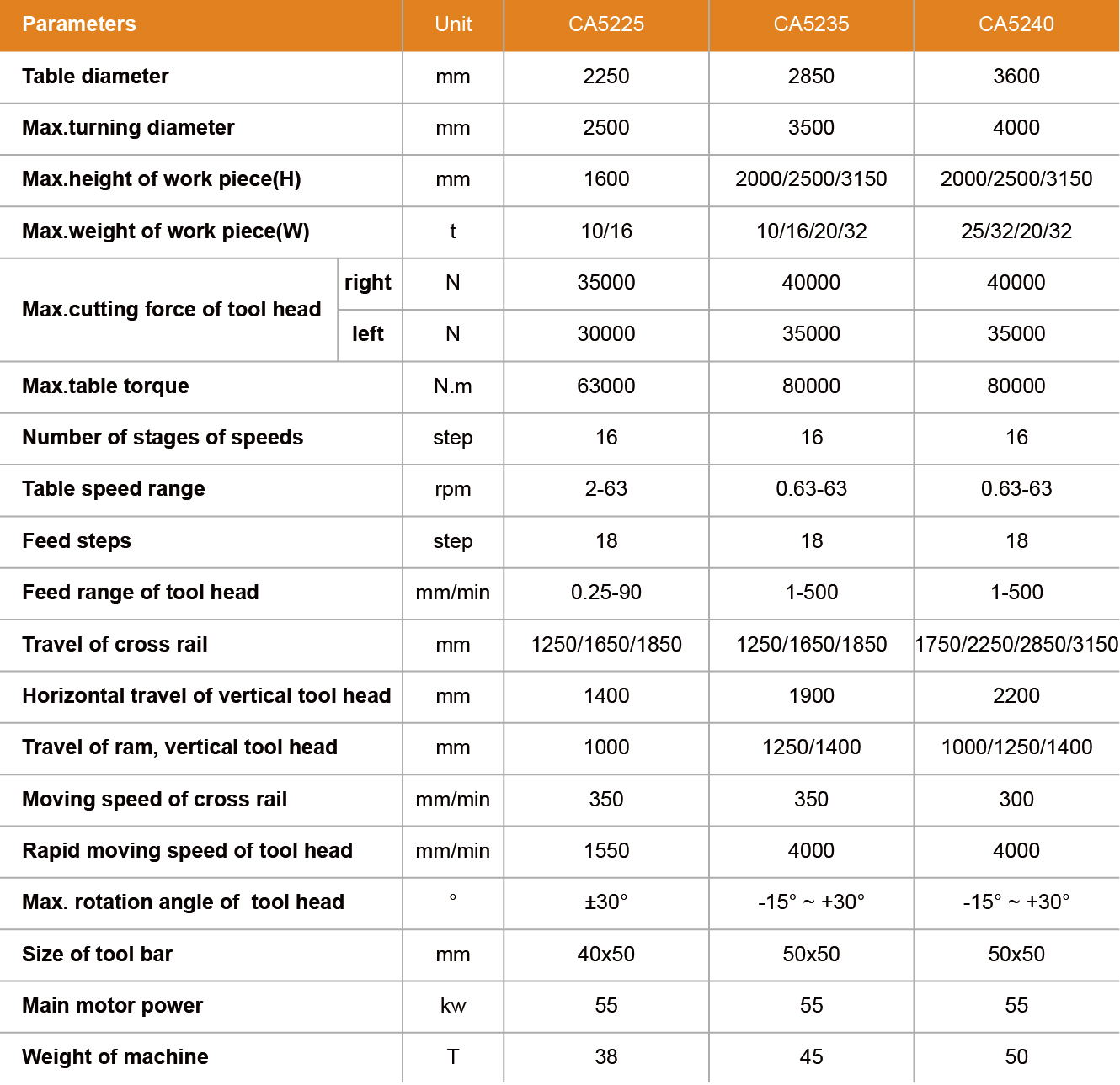

Double column vertical lathe, there are two rest, it is widely used in metallurgical, chemical, electrical, mining, shipbuilding, steel, military industry and other industries of large workpiece machining.This series machine is suitable for hard alloy and ceramic cutting tools, such as for ferrous metal, nonferrous metal and some non-metallic parts of inner and outer cylinder, inner and outer conical surface coarse finishing, end, grooving, etc.Feed driven by ac servo motor, ball screw transmission.Ordinary vertical lathe C52 series of main transmission driven by ac motor, CVT, realize the speed range of the workbench.Also can be chosen according to user's special requirements of dc motor.Main transmission: two levels of mechanical variable speed level 3 speed.The workbench to the thermal symmetric structure.Workbench main shaft adopt high precision adjustable double row short cylindrical roller bearing radial clearance centering.Axial using cross-flow hydrostatic guideway.Make workbench with high rotation accuracy, capacity is big, small thermal deformation characteristics.

Technical performance of main components:

1. High precision, workbench spindle bearing adopts double row roller bearing and bearing the workbench constant current static pressure guide rail.

2. Good rigidity due to the left side of the portal frame column, beam, ram, and the workbench main parts, such as design was optimized by using CAD, according to the degree of vertical lathe steel standard, with optimizing the section size of first, the structure and shape is symmetrical, is machine tool has the static and dynamic stiffness, low thermal deformation, etc.

3. The service life is long, because of the large table guide rail size when work a certain weight, hydrostatic guideway to undertake large area, partial load resistance is strong, the static pressure oil pressure is small, so that the workbench has high service life.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: